Technical Articles

Brake Literature

The precision machining of brake discs

Brake disc engineering involves the precision procedures Disc Thickness Variation (DTV), run-out, Mounting Surface Flatness (MSF), friction surface parallelism, and balance.

DTV・・・Disc Thickness Variation

Disc Thickness Variation is a measure to see if there are any variation in brake disc thickness along the entire braking surface. DIXCEL tolerance is 1/100mm

Run-out

Run-out is a test to see if the disc will spin without any vibration. The parallelism of the mounting surface and the outer friction surface is measured. DIXCEL tolerance is 5/100mm.

(Mounting Surface Flatness)

MSF (Mounting Surface Flatness)

This is a measurement to make sure the disc will not vibrate after installation on the car. The flatness of the disc mounting surface is measured, and DIXCEL tolerance is 5/100mm.

Friction Surface Parallelism

Friction surface parallelism is a check to see if the two friction surfaces are parallel. The parallelism is check on the entire friction surface. DIXCEL tolerance is 2/100mm

Balance

The balance is to check if the weight balance of the disc is evenly distributed. If there is an uneven distribution of weight, it can cause unwanted vibrations. The uneven balanced is fixed by adding balance weight or shaving off excess weight. This is a method taken by car manufacuture’s brake discs.

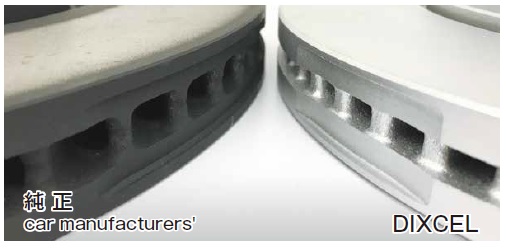

f any of the precision machining standards are not met, the risk of a disc developing juddering will be high. On top of the five precision machining standards, the friction surface of the disc is machined to improve the bedding process of the new brake pads, and provides more stable braking from initial use. The groove between the mounting surface and the friction surface of the disc is designed to optimize the cooling effect, which will prevent thermal cracking and distortion. At DIXCEL, we put all discs through a thorough final product inspection. Be rest assured our products are of the highest quality.